Building a new tractor

Spring is a wonderful, crazy, busy time of year if you're even pretending to be a farmer, like I am. Part of the experience I enjoy is thinking about how they did it all, when everyone was doing this. My dad tells me that his parents bought three things from the grocery store: sugar, flour, and yeast. I can tell you that there is a bit of work involved in getting the rest!

This year we're raising meat chickens. We're a bit reticent about it because we are keen on heritage breeds like we talked about in Talking Turkey, and we'll raise some of the commercial variety to start, but this mission is about getting people introduced to us as a source of food. Well, to be honest, for those who know me, it's more about me being tirelessly addicted to challenging projects (sigh - I have to justify it somehow).

It's really quite an easy sale though. In Ontario you are allowed to raise 300 meat birds per year per farm if you are not part of the commercial industry of valuable quotas and expensive equipment to ensure public food safety (can't blame the system for that), etc. These birds must be sold at the farm gate - no farmer's markets, restaurants, or retailers. Therefore, chicken raised by small farms like ours, on pasture, tasty, and personally cared for as they grow, are automatically in very limited supply, and many people are excited about the opportunity to get some. The farmer must be someone who appreciates something of the experience that motivates beyond any financial gain, which is scant at best. Take me for example: I just like the activity and it prevents me from using my time to do something even more foolish.

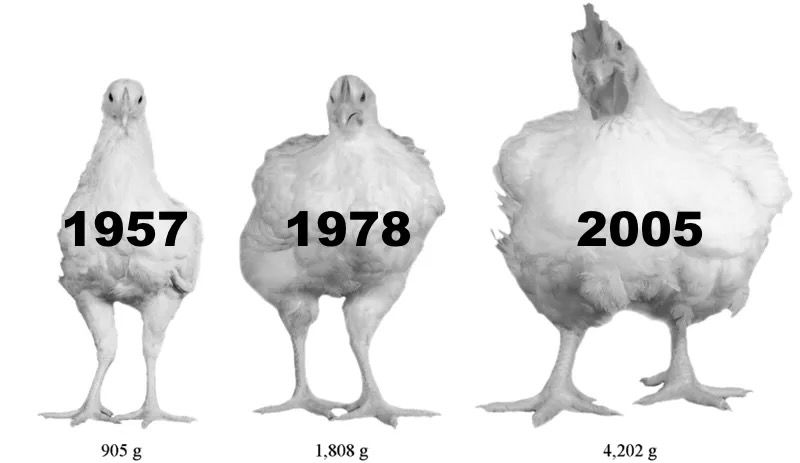

The meat chickens we'll raise are Cornish Cross (or Cornish X), a hybrid bird, the same kind of chicken you buy at the grocery store. We'll grow them a bit longer and larger. The grocery store chicken lived about 4 to 6 weeks, maybe 7, as this maximizes feed to meat conversion. They grow stupidly fast. In fact, you can't have food available to them 24 hours per day because they will eat themselves to death. They grow so big that 12 weeks of age is really the limit, before they get so heavy they can't walk. They don't reproduce. Only the few, factory hatcheries with the breeding stock of the birds that are crossed to make these little meat factories can provide the chicks. Industry started refining these breeds (beginning with a contest!) through selective breeding in the mid-1900's. They did an impressive job, check it out:

The world eats about 35,000,000,000 of these broiler chickens per year, and about 80% of them are hatched by one of three companies. In canada, 2,800 farms raise the chickens, and about 75 processing facilities of scale package it.

Okay so that's the backdrop, and you can probably see why I'm not all that excited about them. On the flipside, the meat we'll produce will be tastier and more nutritious than what we buy at the grocery store, regularly. Baby steps.

First things first, we need the infrastructure to raise them, and if I wasn't writing this I'd be out in the shop building the third of three chicken tractors we need.

It's a fun project and as it happens my mom was talking to a family friend recently who taught some friends and me how to build a rabbit hutch many years ago in 4H, using some of the carpentry methods that this design calls for (lap joints). My sister and I had up to 50 rabbits at one point (so, yeah, I've been like this for a long time).

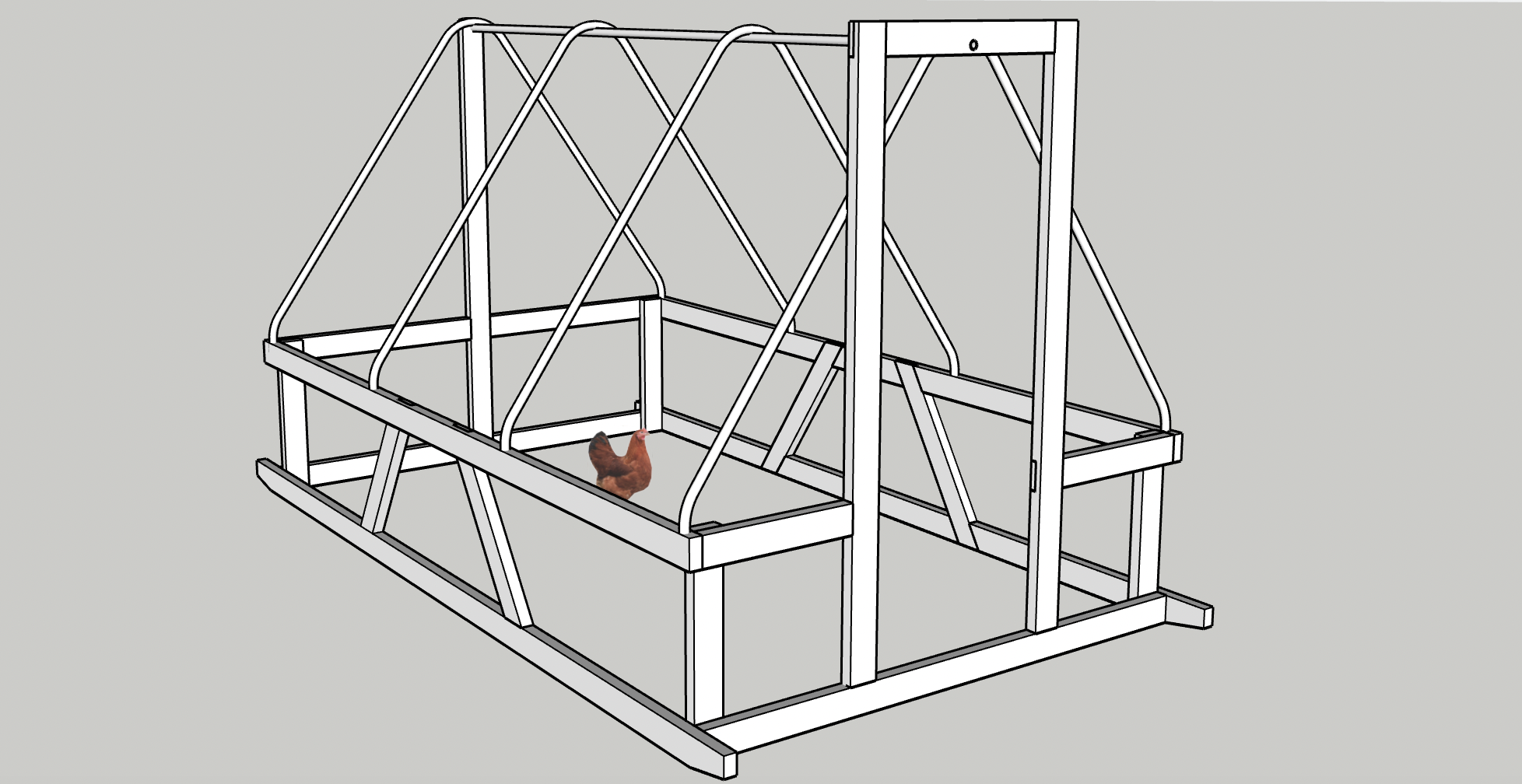

I digress. Chicken Tractor: Movable. No bottom. Protects the birds from predators. Moved to new grass once or twice per day.

I followed a popular design created by prolific YouTuber and small farmer John Suscovich, who actually sold 10,000 copies of a little handbook to show people how to build them. Of course, I modelled it in SketchUp and tweaked a few details because, well, doesn't everybody? I guess 10,000 people didn't. That's kind of weird.

As any small farm must, I have a plethora of building materials hanging around. Wood and parts from building projects, etc. So does my neighbor. Our wives are constantly telling the other to take some of the "junk" we have to the other side of the fence. This design uses 4 lengths of steel conduit tubing. My neighbour had a few laying around. Some were shorter than we needed, but after a bit of welding with my daughter we were in business!

Okay so that's one frame, but I need three. And so off to buy some more of that metal conduit. Sticker shock! $43 per piece! Yeah, no room for that in the ill-advised-to-begin-with-project budget!

Time to improvise. With lots of Eastern White Cedar around (subject of a future post maybe), the next two will be all wood.

Thanks for reading. Send me an email anytime. You can peruse other musings of this wannabe farmer from the homepage, or click on my picture, below.

I have to get back to the shop!